For your heavy duty playgrounds

26.11. – 29.11.2024

Bauma China is once again taking place in Shanghai. We will also be present and look forward to seeing you at our stand in hall N5 - booth number 823.

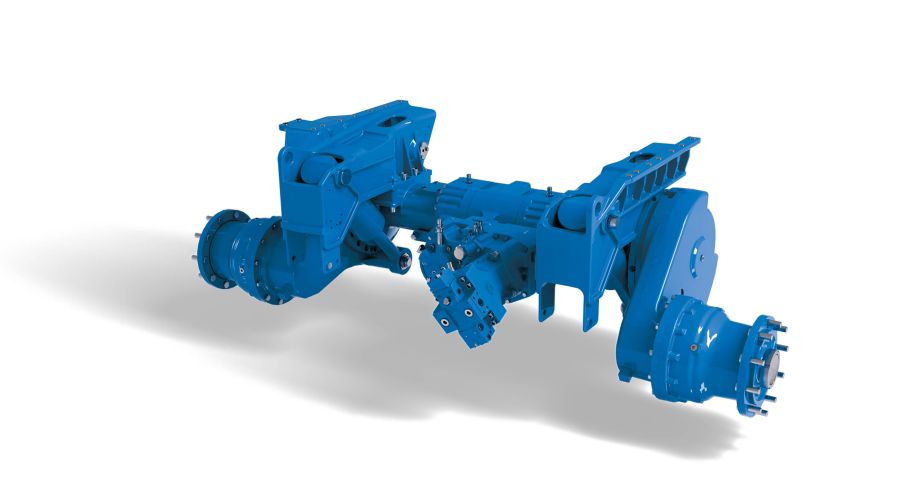

Drive solutions for harvesters

NAF’s products for combine and forage harvesters offer proven dependability in difficult operating conditionsFor more than 25 years, NAF has been a reliable supplier of driveline components for OEM’s of agricultural vehicles. The experience gained during this time can be applied in many ways to different driveline variants in various types of harvesters.

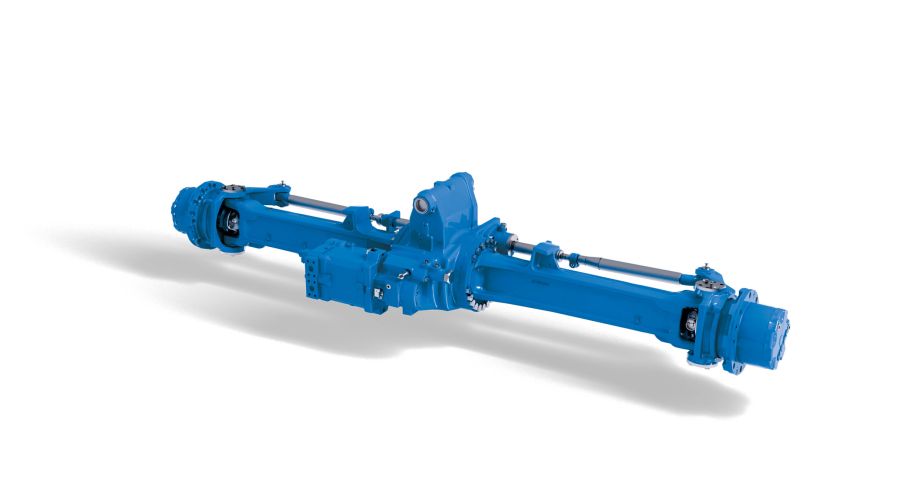

Whether driven steering axles, which significantly facilitate driving combine harvesters and forage harvesters in the most difficult operating conditions through the fields, or front drive axles in various versions, NAF can supply a fully adequate driveline for every application.

All of NAF’s agricultural axles are equipped with a gearbox which can be driven by either a hydraulic motor or an electric motor. The driven steering axles are only engaged when used in the field and can be disengaged for road transport.

Pure mechanical drive solutions

The company offers driven steering axles for a payload range from 8 to 14 tons. It is however important to distinguish between standard driven steering axles and those with track width adjustment so called FlexTrac Axle®.

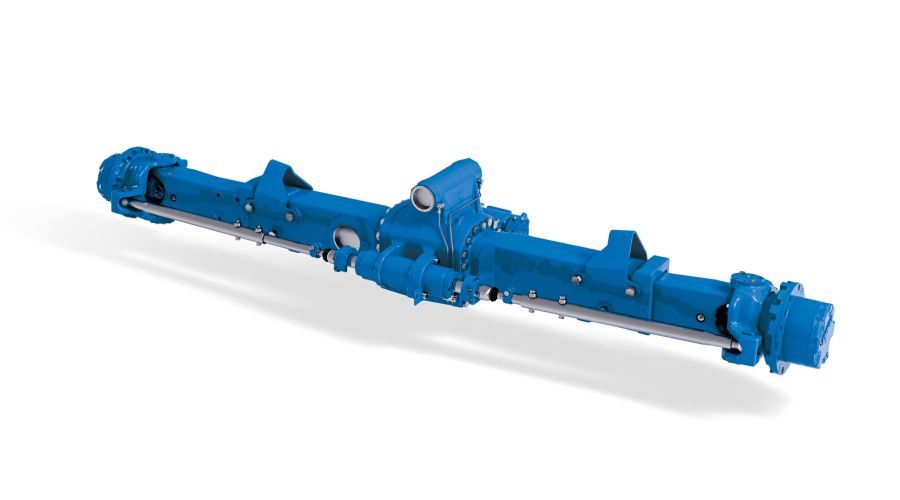

As driven front axles NAF offer standard axles with or without portal/gantry, level control axles in various widths, a split design with differential and separate planetary drives, and of course various bogie axle solutions.

Whether with or without portal/gantry, NAF’s standard front axles bring the highest possible tractive force to the field thanks to the mechanical transmission and serial equipped differential lock. This is the standard solution for all combine harvesters and forage harvesters currently available on the market.

Level control axles are used on slopes. These axles can level the harvester and thus ensure an equal distribution of the grain in the processor, whether it is a shaker or a rotor.

If a splitted design is required as front-wheel drive, NAF also offers the appropriate differentials and planetary gears. These differentials also have an integrated gearbox. The differential lock is also installed as standard.

The oil immersed disc brakes are integrated in the planetary gears and thus directly on the wheel.

This offers a very low-wear and pleasant braking behaviour for driver and machine. This preserves the drivetrain and offers an extremely comfortable braking behaviour for the driver. Regardless of the NAF front axle variant, all its axles have their closed and therefore low-maintenance brakes directly at the wheel.

Most innovative drive solution

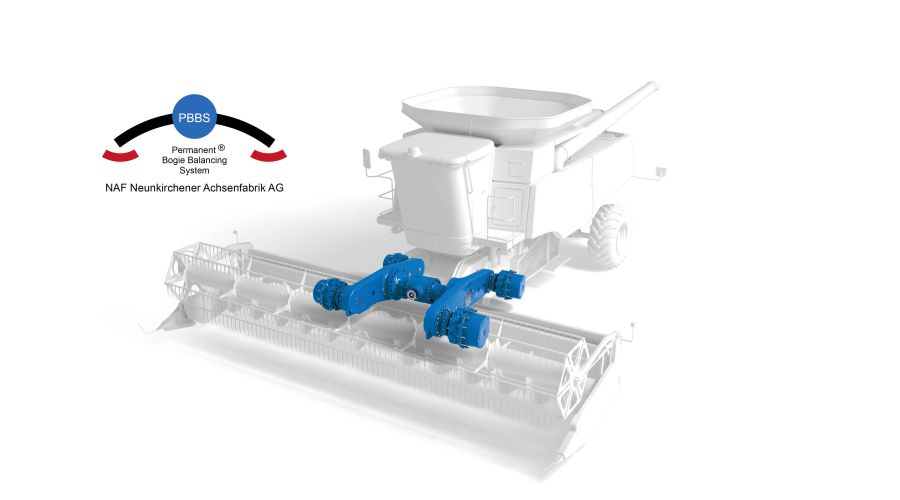

Instead of expensive track systems, NAF offers the significantly lower-maintenance and even more cost-effective drive solution for maximum tractive force. As a supplier of bogie axles in the forestry and construction machinery business and the experience gained over several decades, it was possible to design a product that can compete with the track systems on the market.

PBBS®

The oscillating bogie halves – one on each side of the vehicle – are equipped with NAF’s integrated Permanent Bogie Balancing System (PBBS®). It ensures an equal distribution of weight and tractive effort on all four tires.

The patented PBBS® derives from forestry bogie axles as well. It works with a special gear set inside the bogie that reduces the lifting effect of the bogie front wheels thus providing outstanding off-road capabilities, superior stability and highest tractive effort.

NAF´s modular design allows the integration of single bogie halves as final drives in combine chassis on existing drive and feeder systems. In terms of daily usage the bogie axle gets ahead of track system by far better manoeuvrability and less shear forces on ground during turns.

Additionally, a so-called bogie lift system can be installed which allows to lift the front tires and the machine is solely driving on the rear tires of the bogie axle resulting in better performance and less wear and tear during road travels.

In general, high travel speeds up to 50kph are realised with smooth riding combined with low maintenance costs. Besides its practical advantages the bogie system is also convincing with moderate system expenses combined with low lifecycle costs.

Source: iVT October 2023

For your heavy duty playgrounds

26.11. – 29.11.2024

Bauma China is once again taking place in Shanghai. We will also be present and look forward to seeing you at our stand in hall N5 - booth number 823.

We use cookies on our website. Below you can choose whether and if so, which non-essential cookies you wish to accept and receive further information on this.